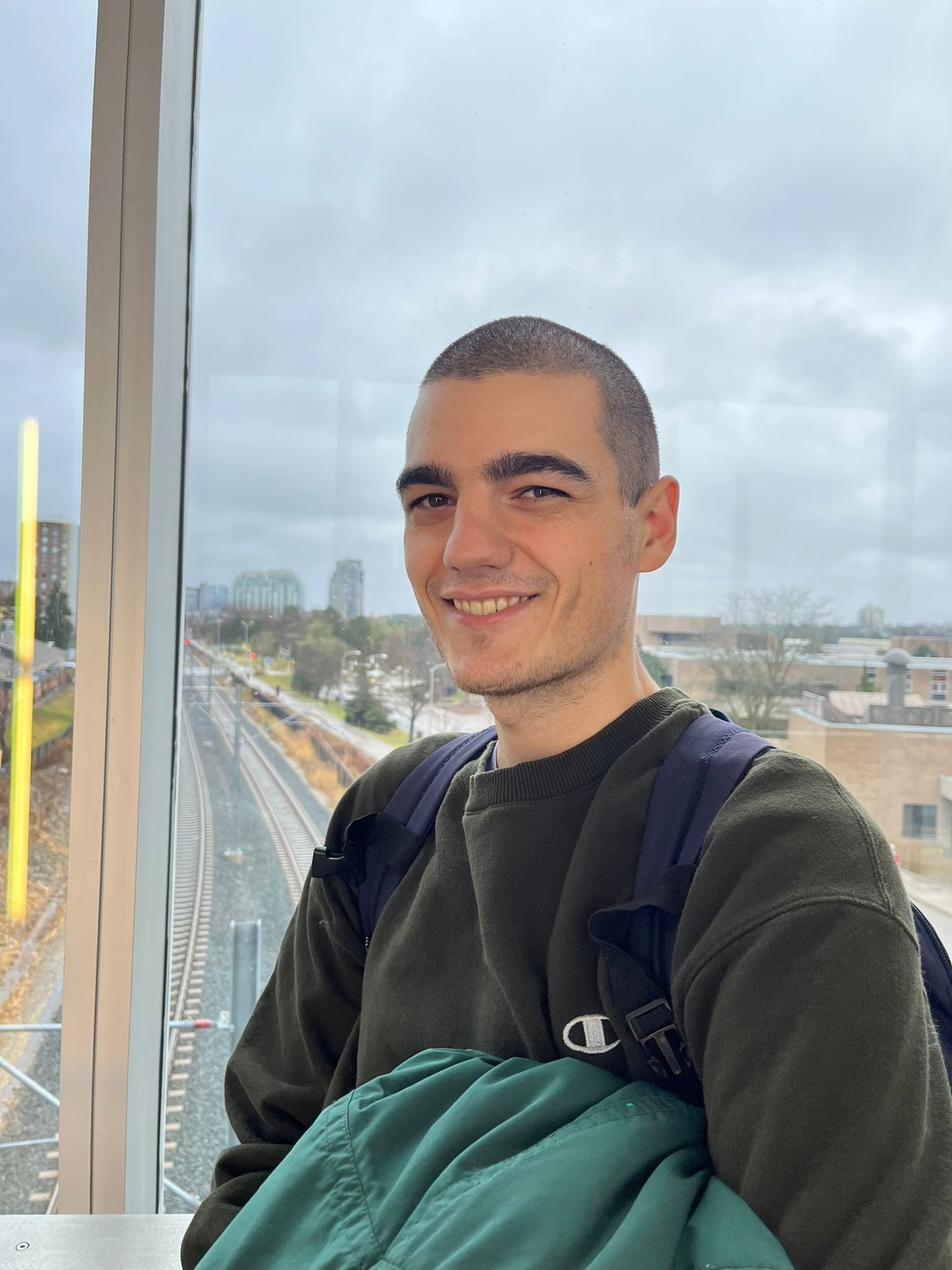

Case Study: Mechanical Engineer in Alternative Proteins

David Moscoe is a mechanical engineering undergraduate student at the University of Waterloo with a passion for mechanical design. He shifted to the Alternative Proteins sector driven by personal values and interest in innovative work. Leveraging his network, he secured a role as a mechanical engineer at New School Foods, a plant-based seafood startup based in Toronto, Canada, where he implemented a co-op program and contributed to factory design.

TL;DR: David Moscoe transitioned into the Alternative Proteins sector, merging his passion for engineering with sustainable food solutions. At New School Foods, he utilized his network and academic insights to innovate in plant-based seafood, emphasizing the importance of networking and adaptability in this rapidly evolving field. Advising others, he emphasizes networking, understanding engineering principles, and rapid learning. Staying informed through active engagement within the industry, David finds its evolving nature both challenging and rewarding.

Can you describe your professional background before you transition into the Alternative Proteins sector?

Prior to working in Alternative Proteins, I was doing a number of jobs. I graduated in April of 2020, directly into the pandemic. While I was job searching, I found myself incredibly uninterested in the idea of working for any engineering role involved in any capacity with oil and gas, or military and weapons for moral reasons. This meant the engineering roles available, especially at the time, were quite scarce. I spent some time as a professional woodworker, some time as a math tutor, and I worked as a tenant organizer, too. I spent some time as a mix of woodworker/engineer at a company making luxury windows and doors but that was mostly technical work without much room or opportunity for creative design.

The bulk of my professional experience came from my co-op experience at the University of Waterloo, whereby every 4 months engineering students alternate between a co-op job and a school semester. There I worked at a number of companies primarily doing consumer product design.

Most notably the Waterloo co-op program has an option for getting a co-op credit for working on your own startup. I actually wound up making and selling high-performance unicycle parts of my own design for a number of years which helped me build up a significant portfolio of work, especially as it was all work I had done entirely independently for every product.

What motivated you to consider a career change from your previous industry into Alternative Proteins?

It aligns with my values, the benefits are nice (at least for the company I'm with), and the work is interesting. It's really that simple!

Can you detail the specific challenges you faced when trying to enter the Alternative Proteins sector?

The food industry in general has a lot that goes into it to ensure sanitation and cleanliness. Designing for food safety is a massive undertaking. There is so much I had to learn about fitting types, general design approaches for cleanability, thermodynamics, and fluid dynamics. Staying on top of everything was and is something I struggle with. Additionally, a constant challenge for the company as a whole is the idea of good enough. We're trying to replicate salmon, but how perfectly do we need to do that? Is salmon that comes in the form of a rectangular prism good enough? Narrowing in on exactly how much of a replica we need to make has been a constant challenge.

How did network or resources help you in securing a position within the Alternative Proteins industry?

My network was frankly the reason I got into the industry in the first place. I was one of the first employees at New School Foods and a friend I worked on my capstone project in undergrad with was the first employee. He recommended me for the role.

Can you share any notable career achievements or milestones you've reached since transitioning to the Alternative Proteins industry?

Working in plant proteins was the first time in my career I was able to implement and oversee a co-op program. It is deeply rewarding seeing younger engineers get the opportunity and experience for their careers in this industry. Working in this industry is also the first time my name will be on a patent and the first time I'm working on a factory floor – the first time I'll be working on a factory floor in terms of the design of said factory at least!

As someone who has successfully transitioned into the Alternative Proteins industry, what advice would you give to others looking to make a similar change?

First, to get into the industry, networking is the most important. I was extremely lucky with my network. The best advice I would give to other engineers in terms of what being qualified means is to understand what engineering is. For me I started working at New School Foods in its infancy, so to this point, most of my role has been R&D and is only now transitioning into scaling up the processes and building out factories.

To me, engineering is a process of optimizations and first principles. From an R&D perspective optimization might mean that if you're making a jig, you might need to make it just good enough because your time is more valuable working on other things than spending another day or week improving the design of your jig. Finding the balance of good enough for a project is invaluable at any startup, especially a young one. Good enough of course is not rhetorical – the design does of course need to actually be good enough to achieve its objective.

Be prepared to learn a lot and fast. There are parts of my job that are daily and secondary to me now that I knew literally nothing about when I joined New School Foods. There is so much to learn, and so much you'll need to learn if you're new to Alternative Proteins or the food industry in general.

This advice is intended for anyone joining a younger company in the Alternative Protein industry. Even now New School Foods has only 20 employees. I imagine Impossible or Beyond Foods are similar in some ways, but these are companies with hundreds of employees – the nature of the work you'd be doing and the processes you do them under would surely be different from my experience.

How did you first become interested in the field of Alternative Proteins, and what steps did you take to pivot your career in this direction?

I became vegan in university and subsequently for my capstone project worked on Alternative Proteins. Learning about the industry was quite fascinating and it is rich with space for innovation and growth. Seeing the huge lack of understanding of what happens inside a twin screw extruder, the most common way to make plant proteins, and seeing the ramifications that has on scalability for the industry makes it a really enticing field as there's so much potential for improvement both in terms of understanding this production method and exploring alternate methods.

In what ways has your previous professional experience influenced your approach within the Alternative Proteins sector?

I have always been self-motivated when it comes to tinkering and making things. It has always been something that deeply interests me and has helped my career tremendously. Physically making things in as many different mediums and with many different tools and processes gave me an intuition for how materials behave, manufacturability constraints, and design for assembly. This skill set helped me acquire internships in undergrad where I was able to then learn so much more about design and engineering. Having this skill set means rapid turnaround in-house for parts I design and need, and an intuitive understanding of materials, manufacturing processes, and design for manufacturability.

Do you have any memorable stories related to your work in Alternative Proteins that you'd like to share?

Getting to tour a university lab in Guelph as part of my capstone project was a fascinating experience. It was incredible hearing from some of the most learned people on the topic, experts in their field, share their insight on Alternative Proteins, and invite us into their labs for a tour.

What have been some of the most rewarding aspects of working in the Alternative Proteins sector for you personally?

Creativity excels with constraints. The constraint of using plants to replicate millions of years of evolution in the form of animal meat necessitates creativity and ingenuity, and the challenges presented in this industry, while sometimes frustrating in the ways they can linger, are truly unique and rich to dig into. Being able to work on some of these challenges, unravel them, and understand the issues has been deeply rewarding. Especially when outside contractors who assure us they can solve the problems we're facing routinely underestimate the scope and complexity of the challenges we're tackling!

How do you stay informed and continue to develop professionally in an industry that is constantly evolving like Alternative Proteins?

For me, I just exist within this industry so I have an entire working week every week where I'm actively trying to be informed. As problems arise and research needs to be undertaken I will do my best to be informed, see what other companies or industries are doing for this problem, and understand the standards driving these decisions.

I make sure I know what I need to at work but because of the novel approach New School Foods uses for production there is not much need for me to be informed on the ins and outs of the plant protein industry as a whole, as the approaches and therefore unique challenges of the industry at large do not reflect us.

Are you looking to start your career in the Alternative Proteins sector? Check out the Tälist job board! With hundreds of new jobs added each week, Tälist connects you with opportunities that align with your skills and passions in the sustainable food industry. Join today and be part of the future of food!